-

Edge Position Control Systems(Sensors)

- Sensor / Electric Type Diagram

- Autowide Sensor AWE280A

- Photohead PH22VAS for vacuum environments

- High-temperature EPC sensor HE120A (for transparent webs)

- Ultrasonic Sensor UH05

- CMOS Linear Sensor SLH30

- Design Position Control DPC

- PHOTOHEAD PH16B / PH21

- PHOTOHEAD PH22

- Ultrasonic Autowide Sensor UHW051

- Ultrasonic Autowide Sensor UHW280

- Ultrasonic Autowide Sensor UHW500 / 700

- LINE FOLLOWER HEAD LH19

- LINE FOLLOWER HEAD LH110

- LINE FOLLOWER HEAD LH500

-

Edge Position Control Systems(Electric type)

- Sensor / Electric Type Diagram

- Guide roller mechanism (Electric type)

- AC servo actuator A353

- AC servo actuator A032

- AC servo actuator A152-□□□-20

- Motor-Driven Actuator K50 K50/A

- Liteguide Controller AE550/AE560

- Linear Actuator K300-200-20

- Compact Guide Roll Mechanism PGR series

- Compact Guide Roll Mechanism LCD series

- Guide Roll Mechanism

- Liteguide Controller AE1000

- Motor-Driven Actuator K12 series

- Motor-Driven Actuator K62 K62/A

- Motor-Driven Actuator K80

-

Edge Position Control Systems(Hydraulic type)

-

EPC related components

-

Tension Control Systems

- Tension Control System Diagram

- Intrinsically safe explosion-proof MB tension sensor

- MJ tension sensor (for vacuum environment) MJ**VAS

- MJ tension sensor (for vacuum environment) MJ**V

- Tension Controller TC920V

- Tension Controller TC680A/D

- Open loop Tension Control System TCD030T

- Tension Meter TM310T

- Tension Meter TM340

- MG Tension Sensor

- MJ Tension Sensor

- CJ Tension Sensor

- MB Tension Sensor

- Electro-Pneumatic Converter EN40

- Other related equipment

-

Automaic Register Control Systems

-

Print-to-cut Register Control Systems

-

Other Related Equipment

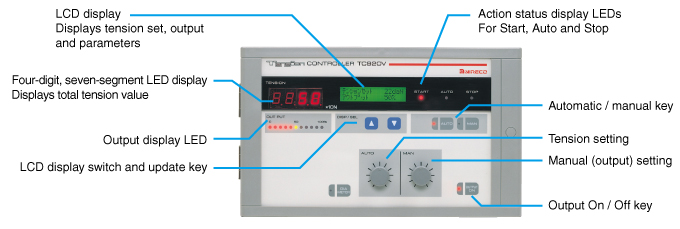

Tension Controller TC920V

Overview

The TC920V Tension Controller can be used with a wide range of web manufacturing and treatment processes to automatically control the tension of a moving web to a constant value. Digital calculation allows a wider range of functions than previous products, but the controller can still be operated in the intuitive style of an analog device. This controller combines stable and precise tension control with excellent cost performance.

Feature

-

Control knobs for frequently-used operations

Control knobs are used for tension settings and manual settings to give a familiar feel.

-

Clear display

A four-digit LED display is used for quick and easy checking and an LCD display for more extensive information.

-

Simple zero and span adjustment on installation

Automatic adjustment functions make adjustment a simple process. Tension control is conducted with the start contact only. The system automatically outputs pre-output on startup, and slack-prevention output on stop.

-

Excellent responsivity and stability

Proportional and integral action are augmented by our renowned fixed loop gain calculation.

-

Connection with a wide range of tension sensors

Can be connected to the following wide range of Nireco sensors: MB, MG, MC, CD, MJ, CJ, TSA, and intrinsically safe TSA sensors

-

Free choice of actuators

Electromagnetic brakes and clutches, pneumatic brakes and clutches and torque motors can be used.

-

Compatible with automatic paper splicing

The new/old spindle switching signal produces paper splicing preset output for paper splicing with little variability.

-

Diameter measurement function

An encoder or other suitable sensor can be connected to measure roll diameter.

Function

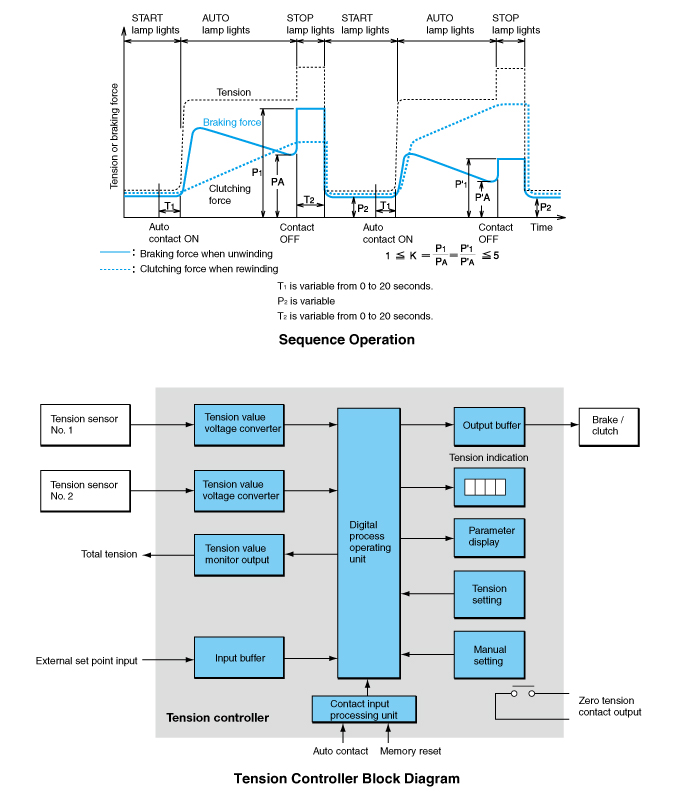

Loop Gain Correction Circuit Provides Excellent Responsiveness and Stability

-

Tension Signal Converter

Digitally display the sum or product of the No. 1 and No. 2 tension sensor tensions.

-

Control Calculator

A control calculator compares the tension signal from the tension display with the target tension, and reduces any variation. Additionally, the ever-popular constant loop-gain control delivers superb control stability and responsiveness, regardless of coil diameter.

-

Output Amp

When the magnetic brake/clutch on the final control element is used, the power of the control signal is increased, and output at 0 to 24 V (4A). When the air brake/clutch is used, 4 to 20 mA is output to the electro-pneumatic converter. When a torque motor is used, a 0 to 10 V (2mA) voltage signal is output to the motor driver.

Specifications

| Power supply voltage | 100 to 240V AC 50/60Hz | |||

|---|---|---|---|---|

| Power consumption | 300VA (Entry cuurent 60Atyp (20ms)) | |||

| Current capacity | 1.5A (200V) | |||

| Mass | 6kg | |||

| Environment | Operating ambient temperature | 0 to +50°C | ||

| Operating ambient humidity | 35 to 85%RH (no condensation) | |||

| Vibration resistance | 3.5mm, 1G, 3 to 150Hz, 3 directions (for one hour) | |||

| Power source noise | 2kV, normal mode, pulse width of common mode 50 nS, 1 uS (depends on the noise simulator) |

|||

| Operating ambient atmosphere | Place free from water droplets, inflammable gas, corrosive gas, corrosive gas, and dust | |||

| Rated tension | 10~10000N | |||

| Tension sensors that can be connected to the TC920V |

MB, MG, MC, CD, MJ, CJ, TSA, and intrinsically safe TSA tension sensors. | |||

| Output | Output for measurement | Tension value voltage output (0 to 10VFS (1 mA or less)) Current output for tension value meter (0 to 1mA/FS) |

||

| External setting power supply | 0 to 10V (1 mA or less), 4 to 20mA (470Ω or less) 0 to 24V (4A or less) |

|||

| Power supply for external setting | Power supply for external setting | |||

| Contact output | Zero tension output Minimum diameter output Automatic control output |

Number of outputs, 3 (DC30V 0.2A, AC200V 0.2A) |

||

| Input | Sensor input | •MG tension sensor •MB tension sensor •MC tension sensor •CD tension sensor •MJ tension sensor •CJ tension sensor •TSA tension sensor |

||

| Analog input | •External tension setting •External manual tension setting |

A number of inputs, 2 (0 to 5V, input impedance 100kΩ) | ||

| •Analog diameter (for Taper and Start level) •New spindle deameter (for splicer) •External start level setting •External taper rate |

A number of inputs, 4 (0 to 10V, input impedance 100kΩ) | |||

| Contact input | •Automatic •Memory reset •Accelerate/decelerate •Splice •Output on •Emergency stop, external automatic / manual or accelerate •Diameter calculation reset •Diameter calculation hold |

A number of inputs, 8 (12V DC, 12mA) | ||

| Pulse generator Gate generator | Detection for speed and diameter | 12V DC | ||

Contact Us

Please use this form to submit your inquiries, feedback and/or requests to NIRECO.